Struct-Fast Product:

Grate-Fast FG

For fastening fiberglass, aluminum, stainless or bronze bar grating to steel beams

Grate-Fast FG

Your choice of fiberglass (or non-corrosive metal) grating presumes a hostile environment. In these applications, drilling the steel (and penetrating coatings) is inappropriate and counter-productive. Instead, fasten your grating with the suitable Grate-Fast Model FG model.

Features:

✓ 300 Series Stainless Steel Investment Casting with reduced body width to fit

closer spacing of 15W, stainless steel bracket and bolts.

Grate-Fast FG (#GF-FG-1—#GF-FG-4)

- 5/16” socket head cap screw bolt, 300 series stainless steel

- Uses 1/4” hex wrench

- Profiled nose to fit on flat or sloping beam flanges

- 3/8” thread engagement for full loading and resistance to corrosion in thread area

- Stainless Steel 300 Series investment casting body

- 14 or 16 gauge, 300 series stainless steel top-hat bracket with one offset wing or flat wings to fit spacing between bars of 5/8” to 2”

- 2-1/4” cap screw bolt length to accommodate up to 2” bearing bar depth*

- Stepped tail fits beam flanges from 1/8” to 3/4”

*Longer cap screw bolts to accommodate applications using greater bearing-bar depths available on special order.

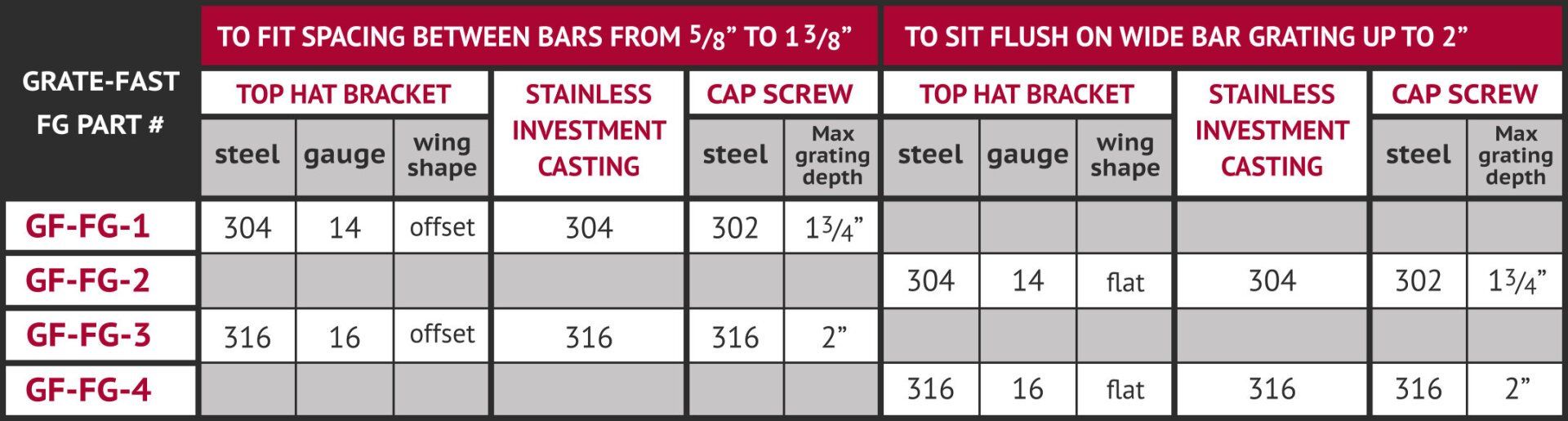

Top Hat Offset and Flat Brackets (see chart for #)

14 or 16 gauge top-hat offset or flat wing brackets also available individually

Grate-Fast FG Installation

Step 1

Position the pre-assembled Grate-Fast with the body between the grating bars and the arrow on the nose pointing toward the steelwork with the top-hat bracket resting on the bearing bars. (Figure 1)

Step 2

Slide the Grate-Fast toward the steelwork until the nose fits under the beam flange. Where necessary, adjust the body/bolt to the approximate flange thickness/grating depth. (Figure 2)

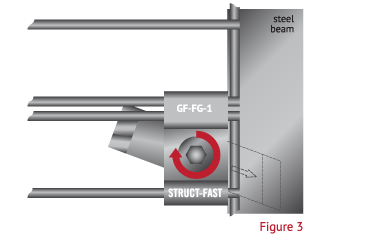

Step 3

Tighten the cap screw bolt using the hexagon key. The Grate-Fast body casting will automatically rotate until it locks under the bearing bar, with the nose under the flange. Continue tightening to the recommended torque. Grate-Fast is now securely in position. (Figure 3)

Grate-Fast FG Specifications

Castings:

› 300 series stainless steel investment casting

› Minimum yield strength: 32,500 psi

› Minimum tensile strength: 50,000 psi

› Modulus of elasticity: 25,000,000 lbs.

› Minimum elongation: 10% in 2”

› BHN range: 110–130

› Machinability: 120

Bracket: ASTM-A 300 series stainless

Socket head cap screw bolt: AISI C1008 300 series stainless

Weight per 100 units: 35 lbs.

Torque recommendations:

Grate-Fast FG: 4 ft. lbs

Ultimate Load: 650 lbs.

Average Side Load

(depending on depth and coating): 450 lbs.