Struct-Fast Product:

Floor-Fast

For fastening floor/checker plate to steel beams

Floor-Fast

Floor-Fast is fast, versatile, & economical

| Features: | ||

|---|---|---|

| ✓ Eliminates scaffolding, welding and drilling of structural steelwork | ✓ One fastener fits flanges from 3/16” to 5/8” | |

| ✓ Requires no access equipment or special tools | ✓ One fastener universally fits beams, channel and angles | |

| ✓ Requires no hole alignment in plates and beams | ✓ Floor-Fast is completely removable |

Floor-Fast

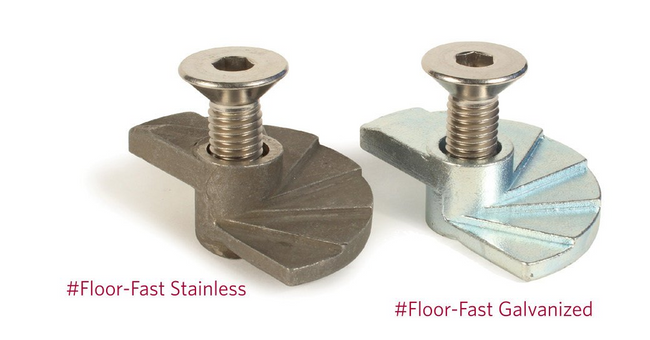

- Counter-sunk flat socket cap screw bolt

- Stepped surface fits flanges from 3/16” to 5/8” *

- Bolts and castings available in both stainless and galvanized (zinc chromate) finishes

- Two bolt sizes: 3/8” (10mm) and 1/2” (12mm)

* The standard Floor-Fast will fit steelwork flanges from 3/16” to 5/8” thickness. If working with thicker flanges, Struct-Fast can furnish longer cap screw bolts and additional packing washers on special order.

Floor-Fast Specifications

Castings:

Malleable iron to DIN 1692, corresponding to ANSI/ASTM A47-84-32510

Tapped for a 1/2” countersunk Flat socket Cap bolt

Cap bolt corresponds to ANSI B18.3 1976

Galvanizing to ASTM Specification B695 Class 50

Weight per 100 units: 34 lbs.

Torque recommendations:

Floor-Fast: 16ft. lbs.

For the FloorFast, we would advise:

- Tension: 2kN/Bolt - 450lbs/bolt

- Slip: 0.5N/4bolts - 112lbs/4bolts

Floor-Fast Installation

Use Floor-Fast to secure steel, aluminum, fiberglass or bronze floor/checker plate to the supporting steel or aluminum framework without field welding, drilling or tapping holes. Secure Floor-Fast to the bottom of the plate, position the plate in the floor opening and with a simple rotation of the socket head cap screw bolt, secure the plate. Simply reverse the installation process to remove the floor plate. No other system is faster to install.

Step 1

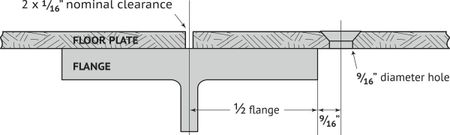

Layout, drill and counter-sink the holes in the floor plate. (Figure 1)

Step 2

Prior to installation, attach the Floor-Fast clamps to the floor/checker plate, positioning the clamp’s straight edge parallel to the edge of the plate (Figure 2). NOTE: The stepped surface of the FloorFast clamp faces toward the underside of the floor plate.

Step 3

Position the floor plate on the supporting framework.

Step 4

Using a hex wrench, release the socket head cap screw bolt one full turn (Figure 3).

Step 5

Tighten down on the bolt. As it tightens, the stepped surface automatically locks under the framework flange (Figure 4).

Step 6

Repeat the operation for each Floor-Fast clamp. Holes in floor plate should be 9/16” diameter, counter-sunk to accept the standard 1/2” counter-sunk flat socket cap screw bolt. Measure the positioning of the center of the hole drilled in the plate according to Figure 1.